By Michelle Price

Special to the UCBJ

MCMINNVILLE – A new era in training and career development kicked off in McMinnville as community leaders, educators, politicians and industry leaders gathered to celebrate the opening of the Motlow State Automation and Robotics Training Center (ARTC). The 12,500-square-foot facility is located on 4.5 acres of land, donated by the Warren County Commission, adjacent to the Motlow State and Tennessee College of Applied Technology campus.

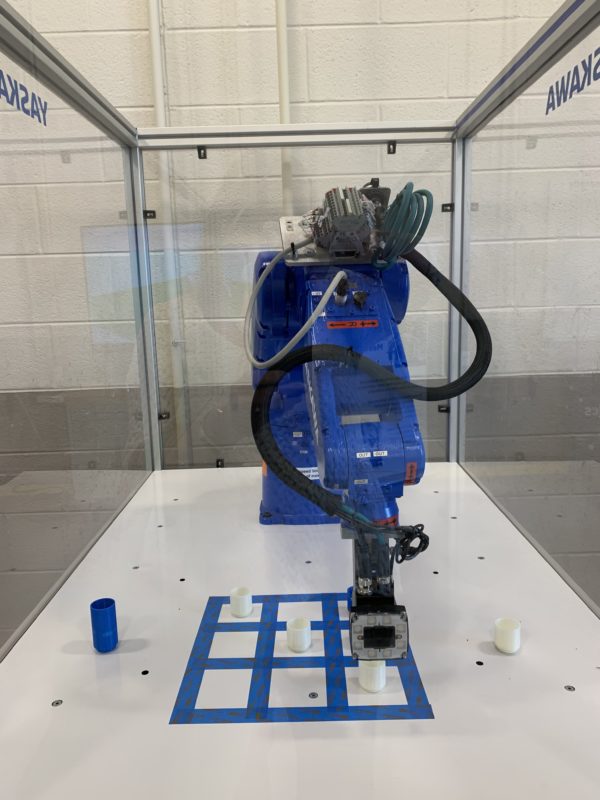

The training facility has six teaching laboratories featuring industrial robots from ABB, Vanuc and Taskawa Motoman, the three largest industrial robot companies worldwide.

“We are so proud of what will be accomplished with this facility,” said Tennessee Board of Regents Chancellor Dr. Flora Tydings. “There is not another facility like this anywhere in the state of Tennessee, nor within a 500-mile driving distance. People will be coming from all over the country to take advantage of the training at Motlow State.”

Tennessee Commissioner of Economic and Community Development (TNECD) Bob Rolfe shared his insights on manufacturing trends worldwide.

“We travel the globe to recruit these companies and at the end of the day in the new world and the new order, it’s about automation,” said Rolfe. “It’s where automation crosses and intersects with technology, what we have at the end of the day is robotics.

“What we also have when it comes to robotics is machinery that bats 1,000 percent. Why is that important? That particular machine does not take breaks, that particular machine truly does work seven days a week, 24 hours a day. And ladies and gentlemen, that is the future. But at the end of the day, the good news is that these machines are going to require human capital to manage those assets. The best news about those jobs of the future is that they require a skilled, trained workforce.”

Motlow conducted a needs and demand assessment during planning for the ARTC.

“What we learned is there are over 7,000 robots within a 75-mile range of this facility,” shared Tydings. “That’s today. So, imagine what’s going to happen over the next several months, years, decades. We’ve got to be ready.”

Larry Flatt, executive director of ARTC, reflected that the facility was one of the only facilities that offers both industrial certifications and academic degrees in the U.S. It is a partnership that others across the U.S. are trying to emulate.

“This is a magnificent facility,” said Geno Casa, ABB executive. “It’s the only one I know of anywhere that has the world’s three largest robot companies all partnered together.”

The robotics center was a natural offshoot of the mechatronics program that Motlow began almost 10 years ago.

“It started almost three years ago when industry, business, the college and local government came together and said we need to have trained and skilled employees who can stay here, work here, make a living here, grow their families here,” Flatt explained. “So with that seed, the response has grown to the point that we now are partnered with the three major robot manufacturers in United States, we have a first class in May, and people are embracing us pretty much in the entire region if not the U.S.”

The first class in May is already half filled.

“That class is an industry class, and they are the exact same classes for the first six months taught by the same instructors as if you went to there (the robot manufacturer’s plant),” said Flatt. “An ABB instructor will come here, we’re in a revenue sharing agreement, and so you stay here for four to four-and-a-half days depending on the class. You will receive the industry certificate from ABB with a Motlow certification sticker on it too.”

The next six months will be busy at ARTC with nine classes scheduled for ABB, 14 for Motoman, and classes for FANUC that are still being scheduled.

“We’re looking to run probably 30 to 40 classes and these are just the certification classes,” said Flatt.

An A.A.S. degree in mechatronics with a concentration in robotics will also be offered starting in August.

Motlow will host an open house at the ARTC, 225 Vo-Tech Dr., McMinnville on Wednesday, May 8 from 10 a.m. to 2 p.m. For more information contact Michelle Cox at 931-393-1760.