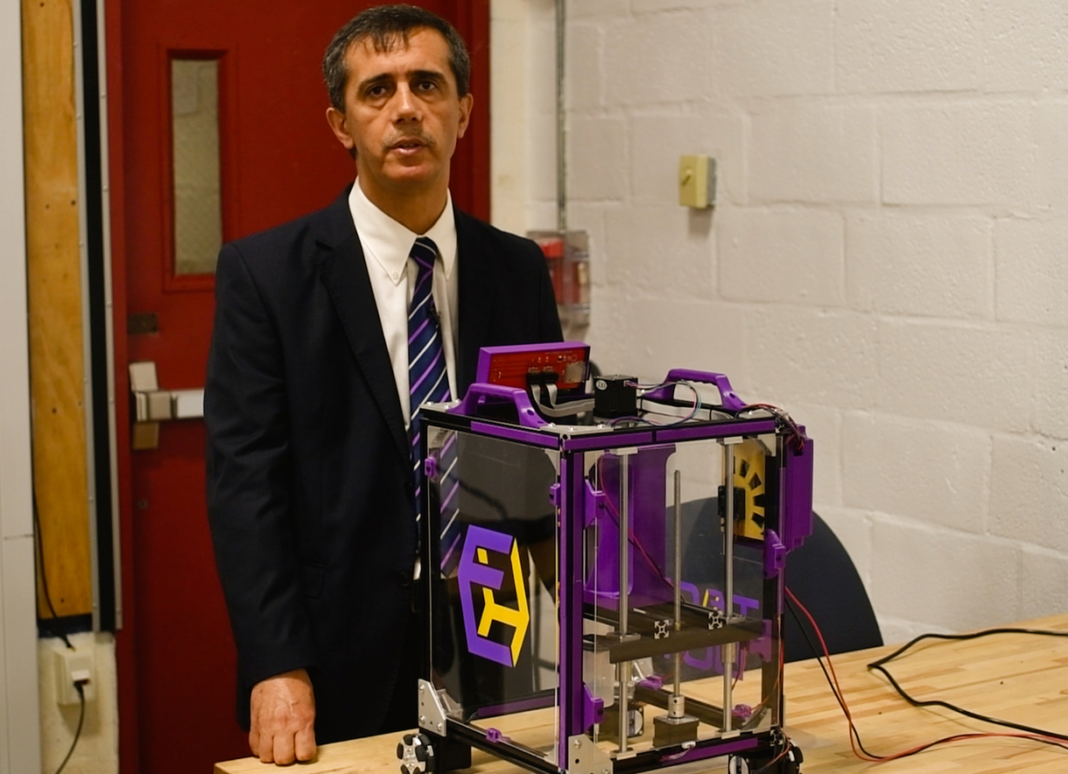

| TechBot to be presented at a conference in Washington, D.C. A mobile multitasking 3D printer created by Tennessee Tech faculty and students will be on display in Washington D.C. in a couple of weeks. Ismail Fidan, professor in manufacturing and engineering technology, and some of his additive manufacturing students will present TechBot at the 26th National Advanced Technological Principal Investigators’ Conference, Oct. 26-28, in Washington, D.C. “What we do with the TechBot is in line with the mission of the university. It’s technological innovation,” said Fidan. “What we do with TechBot is a sample of what we do at Tennessee Tech.” TechBot was designed, developed and fabricated solely by the faculty and students at Tech. A provisional U.S. Patent has been received due to its unique feature of dispensing many different paste-type materials like concrete and solder in any x and y direction. It is also different from any other 3D printers because it is mobile and does not use filament, powder, laser or resin found in other additive manufacturing processes. Potentially being used in several manufacturing and construction facilities, TechBot can make anything from circuit boards to concrete structures. And because it can dispense any paste-type material, including food, TechBot has already been used to make cakes, pies and desserts. “It is fully functional,” said Fidan. “We feel that the initial development is complete.” Fidan says he has been the lead investigator, brainstormer and motivator on the research team. Michael Allen, professor of math also helped the team as co-lead. Tech students, Fidan says, have also done all the hard work which includes the constructing and testing. “The beauty of the TechBot is that we built it from the ground up and we watched it emerge from the ground up and be successful,” said Andreas Sauter, a graduate research assistant. “My main focus was getting the TechBot to run the electronics and getting it programmed to where it would act as mobile 3D printer and precisely print the small and big samples we want to achieve with this platform.” Sauter has been using three different material and printing parameters – frosting, cement and clay – with the TechBot. In doing so, he says he has discovered multiple parameters for how each substance stacks up. “It’s been a success so far. I think the possibilities are endless,” said Sauter. “The budget is the limitation.” Funded through a National Science Foundation award, Additive Manufacturing Workforce Advancement Training Coalition and Hub, TechBot was constructed for $420. While the TechBot platform is available as a kit that must be assembled, it can be put together by consumers of many ages because of its simple components and uncomplicated assembly procedures, allowing it to remain priced under $500. This makes TechBot valuable and affordable for a larger range of customers, including many families and small businesses. TechBot is the key to large-area printing with multiple materials. But, in order to print some larger size objects, there must be more funding for the research. “Our objective is to print some large size objects like appliances or a chair or something like that,” said Fidan. “We will ask the program director to supplement the funding.” The conference Fidan and the students will be attending is presented by the American Association of Community Colleges with the support of the National Science Foundation. The conference is by invitation only and will bring together approximately 850 NSF ATE grantees and their project partners to focus on the critical issues related to advanced technological education. Key people working on ATE projects across the country participate in the conference. Conference attendees represent community colleges, business and industry, secondary school systems, and 4-year colleges covering projects in a wide variety of areas, such as information technology, engineering technology, micro- and nanotechnologies, chemical technology, biotechnology, and others. |