COOKEVILLE — For 12 years, Tennessee Tech’s Industrial Assessment Center has been conducting free energy assessments of manufacturers across the state while training students in industrial energy efficiency.

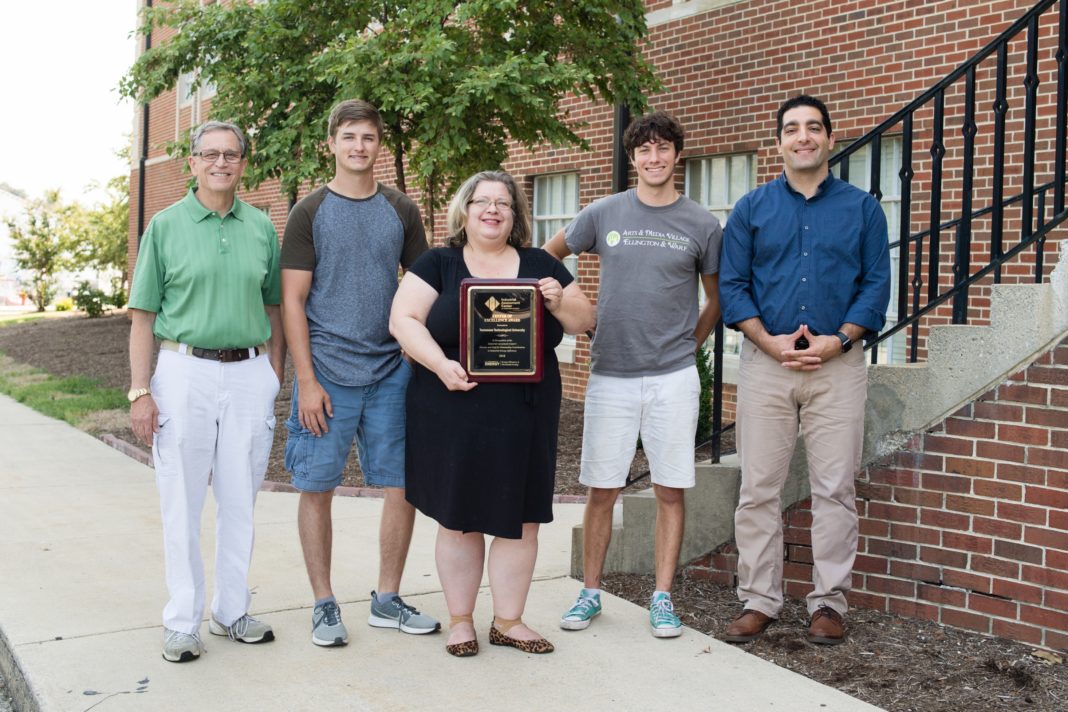

A program of the U.S. Department of Energy’s Advanced Manufacturing Office, Tech’s Industrial Assessment Center is the only funded IAC in the state and one of 28 centers nationally. It is also one of the best. Tech was recently honored with the 2018 Center of Excellence award among a field of centers from universities such as Georgia Tech, Clemson, Kentucky, Alabama, Florida and Miami.

“This program is long-standing,” said Glenn Cunningham, director of the center. “It is quite an honor amongst people who do this kind of work. It’s a pretty elite group of individuals who lead and participate in doing these assessments.”

Tech’s IAC has assessed 210 small and medium-sized manufacturers defined by the Department of Energy as those with annual energy costs between $100,000 and $2.5 million. Local plants that have been assessed include Apcom, Flexial, Tutco, Ficosa, and Crossville Ceramics.

“We consult with companies who want to develop a comprehensive energy management program and help them develop a system in-house that complies with ISO 50001, which is an international standard for energy management,” said center coordinator Michelle Davis. “This is a beneficial, free program to have a team of highly-trained and skilled faculty and students come into their plant, look at their equipment and make recommendations on how they can become more energy efficient and save money on their electric and gas bills.”

Besides the energy assessments, Tech’s IAC assists with cybersecurity assessments, water and wastewater facilities assessments, and conducts workshops on industrial energy efficiency for manufacturing end users.

“Our center initiated cybersecurity assessments utilizing Tech’s Cybersecurity Education, Research and Outreach Center,” said center associate director Ethan Languri. “That has been beneficial to small and medium-sized companies who don’t have a cyber expert.”

The program is also beneficial for undergraduate and graduate students who learn skills and gain experience in industrial energy efficiency and energy management. More than 160 students have been trained at Tech’s IAC.

“Sitting in a classroom you don’t get the hands-on experience,” said Kade Howard, a mechanical engineering graduate student from Sparta. “Once you are in the plant, everything you have learned comes back to you.”

“The first few assessments you have a lot of information being thrown at you all at once,” said Joshua Daugherty, a mechanical engineering graduate student from Nashville. “After you go through a few assessments, you see that each plant is different but have the same properties. I think it has been a good experience for me just taking school knowledge and applying it to the real world.”

A typical assessment by Tech’s IAC includes a team of faculty and students making a visit to a plant to collect data and take measurements of the largest energy-using equipment. The team then writes up a report with specific recommendations of projects to reduce energy usage. The results are approximately $50,000 in recommended savings.

“It’s one thing to sit in a classroom and draw a crude diagram of a pump or an air compressor and start writing equations on the board,” said Cunningham. “This is a real world working experience. It’s not just a classroom or a homework problem.”

The real work experience the students gain in participating in the assessments and being part of the center pays dividends after graduation.

“IAC students are in big demand with employers, especially in the growing field of energy management and energy efficiency,” said Davis. “Some of our recent graduates have received multiple offers and started working right after graduation in the energy field.”

For more information on Tech’s IAC, go to https://tntech.edu/iac.